Re-roofing Southside Aloe Building

using Big River Lines

Three Tab Shingles

The warehouse located

at Aloe siding is operated by Southside Aloe works. I built the

building in 1992, and it has lived outside for 12 years now. As

with real buildings, the roof is the first to go due to weather.

This was my first attempt modeling asphalt three tab singles.

I found a laser cutter who produced a pile of shingles using thick

paper for the material. I hoped that painting the finished roof

would be enough protection. This turned out to be optimisitc thinking.

One of the problems with modeling outside is the final results

may not come back for years. These shingles held up for about

8 years, but I had to replace some of them to prepare for the

2000 National Convention we hosted in San Diego. Four years later,

the roof had deteriorated even further.

I have recently made

a second attempt to produce Three Tab Shingles. This time I found

a gasket material that can be successfully laser cut, and had

a bunch of sheets made up by John Clark, of Fall River Productions.

I re-roofed this building using these new shingles.

The first step was

to remove all the old shingles, and sand the roof flat.

I have recently made

a second attempt to produce Three Tab Shingles. This time I found

a gasket material that can be successfully laser cut, and had

a bunch of sheets made up by John Clark, of Fall River Productions.

I re-roofed this building using these new shingles.

The first step was

to remove all the old shingles, and sand the roof flat.

Start by cutting each

row of shingles apart from the sheet. There are four short attachment

areas that need to be cut. I used an X-acto knife, but any sharp

blade will do. Next, check to see that all the notches are free

of the cut material. Some will have the little pieces still attached.

Remove them before gluing the strips to the roof.

These shingles are

laid just like real shingles. The shingle sheet has a 1/4"

strip at the bottom edge, which is used as the starter course

at the bottom of each roof surface. The shingles are laid starting

from the bottom, with the notches pointing down. Each row of shingles

is offset 1/3 of a tab width, so that the notches only line up

on every third row. This next photo shows the first few rows installed.

Start by cutting each

row of shingles apart from the sheet. There are four short attachment

areas that need to be cut. I used an X-acto knife, but any sharp

blade will do. Next, check to see that all the notches are free

of the cut material. Some will have the little pieces still attached.

Remove them before gluing the strips to the roof.

These shingles are

laid just like real shingles. The shingle sheet has a 1/4"

strip at the bottom edge, which is used as the starter course

at the bottom of each roof surface. The shingles are laid starting

from the bottom, with the notches pointing down. Each row of shingles

is offset 1/3 of a tab width, so that the notches only line up

on every third row. This next photo shows the first few rows installed.

I used a new glue,

TiteBond 3, which is a good wood glue, and is formulated to be

waterproof. I haven't used it before, but I trust the TiteBond

brand, and decided to give it a try in this application.

I found that the following

technique worked very well. Spread a thin layer of glue, about

1/4" wide, along the entire roof length, just above the previously

installed row.

I used a new glue,

TiteBond 3, which is a good wood glue, and is formulated to be

waterproof. I haven't used it before, but I trust the TiteBond

brand, and decided to give it a try in this application.

I found that the following

technique worked very well. Spread a thin layer of glue, about

1/4" wide, along the entire roof length, just above the previously

installed row.

Carefully place the

next row in the glue, lightly pressing each tab into the glue.

This material can curl, so the lower edges have to be securely

glued.

Carefully place the

next row in the glue, lightly pressing each tab into the glue.

This material can curl, so the lower edges have to be securely

glued.

Look at the back side

of the row, to make sure that every tab is covered. Notice that

there is still plenty of glue on the roof to secure the upper

edge of the row.

Look at the back side

of the row, to make sure that every tab is covered. Notice that

there is still plenty of glue on the roof to secure the upper

edge of the row.

Position the row in

it's correct location. This row is set flush with the left edge

of the roof. You can see the previous rows are offset 1/3 tab

width at each level. If all the notches were lined up, the water

would channel as it runs off, and wear out the roof more quickly.

The lower edge of the tabs should just touch the top of the notches

in the previous rows. Securely press the new row in place along

it's entire length. Make sure it is secure to the previous row,

and the original roof surface.

Position the row in

it's correct location. This row is set flush with the left edge

of the roof. You can see the previous rows are offset 1/3 tab

width at each level. If all the notches were lined up, the water

would channel as it runs off, and wear out the roof more quickly.

The lower edge of the tabs should just touch the top of the notches

in the previous rows. Securely press the new row in place along

it's entire length. Make sure it is secure to the previous row,

and the original roof surface.

Some glue will squeeze

out. Wipe off the excess with a damp sponge, using long strokes

parallel to the rows. Wood glue can be cleaned up very easily

at this stage, and leaves a better final product. I found that

I got better at glue application as the job progressed, and less

material squeezed out.

Some glue will squeeze

out. Wipe off the excess with a damp sponge, using long strokes

parallel to the rows. Wood glue can be cleaned up very easily

at this stage, and leaves a better final product. I found that

I got better at glue application as the job progressed, and less

material squeezed out.

Use a sharp stick to

do a final clean right up against the lower edge of the tabs.

Use a sharp stick to

do a final clean right up against the lower edge of the tabs.

I worked from left

to right, and let the right hand edge rows just run long, and

trim them at the end.

I worked from left

to right, and let the right hand edge rows just run long, and

trim them at the end.

This side is done,

and I have begun to trim the lower left hand edge using a new

Xacto blade.

This side is done,

and I have begun to trim the lower left hand edge using a new

Xacto blade.

Both edges are now

trimmed and I am ready to start the other side.

Both edges are now

trimmed and I am ready to start the other side.

Notice that the top

row covers more of the previous row than normal. This allowed

the top edge to be aligned with the exact peak of the roof. It

will make it easier to install the ridge cap pieces. The plumbing

vent and the smoke jack are installed as the shingles are laid,

following standard construction procedures.

Notice that the top

row covers more of the previous row than normal. This allowed

the top edge to be aligned with the exact peak of the roof. It

will make it easier to install the ridge cap pieces. The plumbing

vent and the smoke jack are installed as the shingles are laid,

following standard construction procedures.

The second side has

been finished and the roof ridge cap has been installed. These

are small pieces, one tab wide, are cut from the trimmings of

the roof shingles. I bent each cap piece before installation,

but the material was too thick to stay securely glued. I had to

remove the pieces, glue them together as a long chain, and then

bend the entire chain across a piece of stiff sheet metal. I then

glued the entire chain in place, and clamped it down using lead

weights resting on a couple of wooden sticks, placed right at

the roof ridge. The next morning everything was tight and secure.

The second side has

been finished and the roof ridge cap has been installed. These

are small pieces, one tab wide, are cut from the trimmings of

the roof shingles. I bent each cap piece before installation,

but the material was too thick to stay securely glued. I had to

remove the pieces, glue them together as a long chain, and then

bend the entire chain across a piece of stiff sheet metal. I then

glued the entire chain in place, and clamped it down using lead

weights resting on a couple of wooden sticks, placed right at

the roof ridge. The next morning everything was tight and secure.

I wanted the roof to

be green to match the basic building. After maskinig the rest

of the building, I sprayed with Rust-Oleum Painter's Choice chalkboard

green, which is a matte finish. Make sure you take your time,

hold the spray perpedicular to the roof, and fill all the little

notches. I have seen asphalt shingles in black, brown, white,

red, and green.

I wanted the roof to

be green to match the basic building. After maskinig the rest

of the building, I sprayed with Rust-Oleum Painter's Choice chalkboard

green, which is a matte finish. Make sure you take your time,

hold the spray perpedicular to the roof, and fill all the little

notches. I have seen asphalt shingles in black, brown, white,

red, and green.

The edges of roofing

material are the most vulnerable to weather, so flashing is used

to cover them. I use 1/8" x 1/8" brass angle for this

purpose. These pieces were removed from the previous roof. I cleaned

out the old caulking (black silicone), sanded the insides for

a good bond, and secured them with Plumber's GOOP.

The edges of roofing

material are the most vulnerable to weather, so flashing is used

to cover them. I use 1/8" x 1/8" brass angle for this

purpose. These pieces were removed from the previous roof. I cleaned

out the old caulking (black silicone), sanded the insides for

a good bond, and secured them with Plumber's GOOP.

Here is the building

with the completed new roof. It looks a lot better than when I

started!!

Here is the building

with the completed new roof. It looks a lot better than when I

started!!

Six Months Later

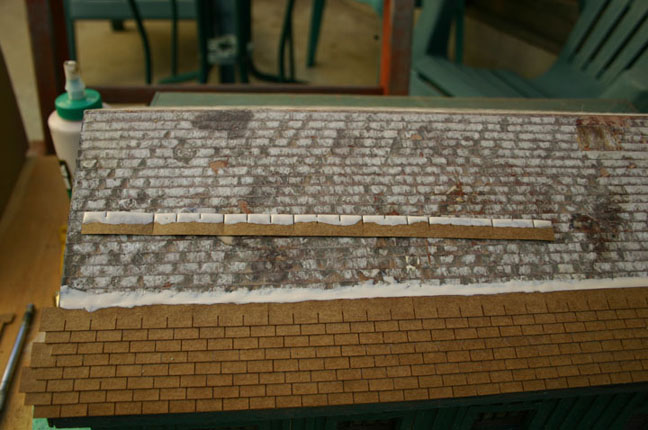

Here is are two detail

shots showing how these shingles hold up over time. This building

lives under a tree, which shades it almost completely. We have

had 20" of rain this winter, which is three times normal

for San Diego. You can see that some of the tabs have lifted and

cupped. It is very important to make sure that every tab is completely

glued down to the layer below. I sprayed the roof green after

it was completed, so the brown natural color of the material shows

where the shingles have lifted. Next time, I would spray the entire

sheets before cutting the rows apart and gluing them down. That

way even if the shingles moved a little, the brown wouldn't show.

I am pleased with how

this material holds up. It's only been 6 months, but the roof

is much better protected than the paper shingles I was using before,

which depended totally on the paint to protect the material. This

gasket material should last for many years, even if it's already

starting to look like a used roof.

Six Months Later

Here is are two detail

shots showing how these shingles hold up over time. This building

lives under a tree, which shades it almost completely. We have

had 20" of rain this winter, which is three times normal

for San Diego. You can see that some of the tabs have lifted and

cupped. It is very important to make sure that every tab is completely

glued down to the layer below. I sprayed the roof green after

it was completed, so the brown natural color of the material shows

where the shingles have lifted. Next time, I would spray the entire

sheets before cutting the rows apart and gluing them down. That

way even if the shingles moved a little, the brown wouldn't show.

I am pleased with how

this material holds up. It's only been 6 months, but the roof

is much better protected than the paper shingles I was using before,

which depended totally on the paint to protect the material. This

gasket material should last for many years, even if it's already

starting to look like a used roof.