One of the functions I wanted to service with WTC was hauling dirt and rocks. I built a set of three side dump hopper cars to carry this kind of load. After researching various prototype examples, I decided on a central spine, tilting bed, with the sides lifting as the bed tilted.

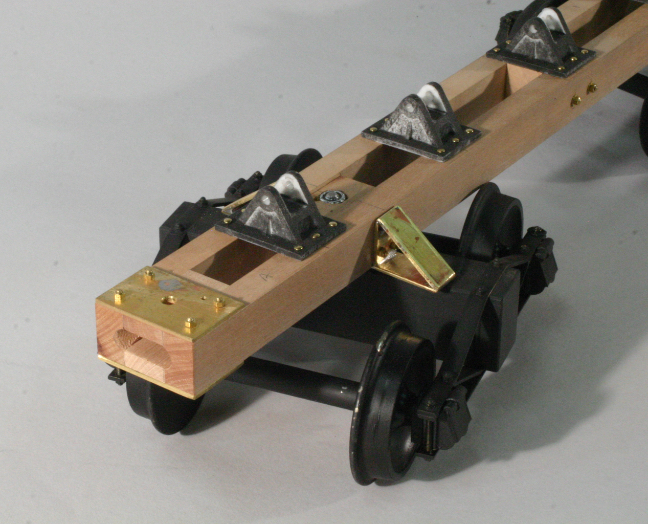

The spine is fabricated from Madrone, through bolted at the truck bolster and the midpoint with 2-56 threaded rod and nuts. The bed pivots on five pedestal bases that were 3D printed and nailed down to the wooden spine. The coupler pockets are strengthened with brass plates top and bottom. Brass stabilizers spread the tilting load to the trucks. This is the end view of the fabricated spine before painting.

Here is the side view of the spine sitting on the trucks.

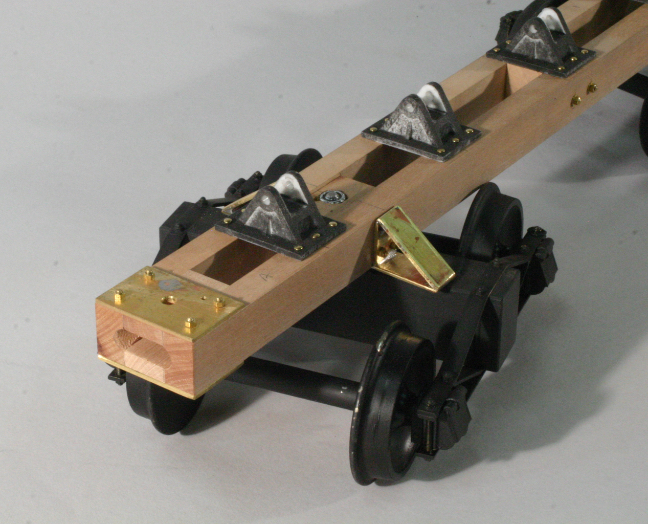

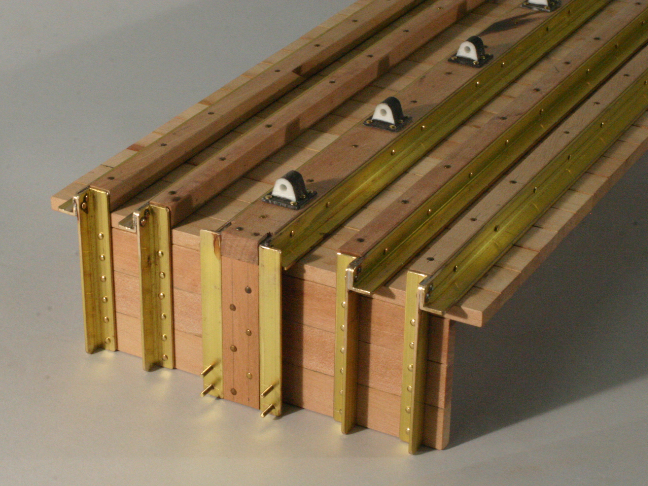

The bed is also made of Madrone, and the ends are strengthened using brass angle stock. The end supports are pinned to the horizontal members supporting the base of the bed. This is the bottom view of the bed with the first beam assembly is attached. A brass angle section is attached to either side of a Madrone spine, showing the upper half of the pivot pedestals. The threaded rods protruding from the end members are the anchor post for the mechanism that lifts the sides when the bed tilts.

Here is the completed bed assembly with all the support frames and end boards installed.

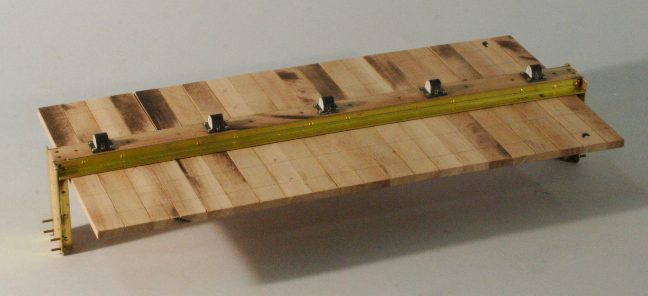

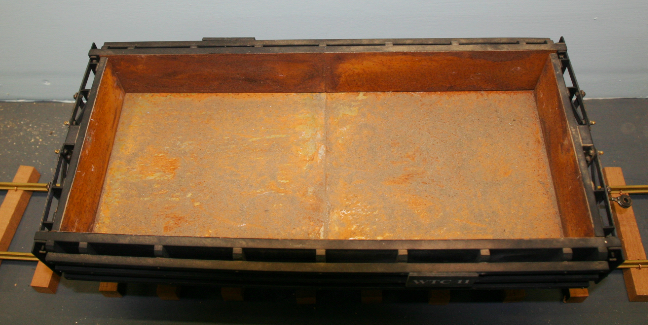

Here is a top view of the complete bed assembly.

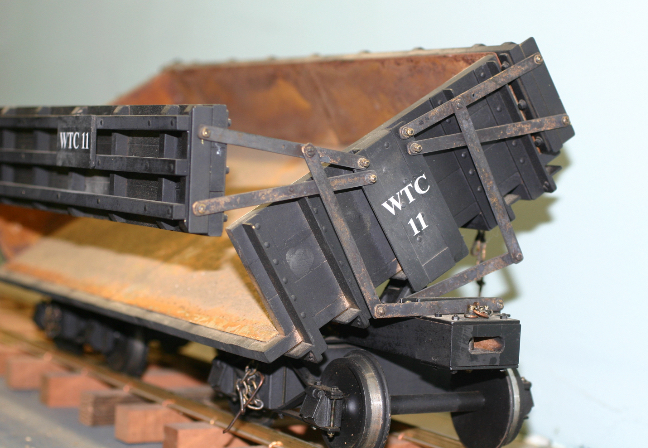

This shows the side detail of the completed hopper, painted and decaled. The bed is kept level during transit by being chained to the trucks on each side. Before tilting, the chains on the uphill side are released.

As the bed tilts, arms lift the side allowing material to slide off the bed. This shows the side lifting mechanism before tilting, and after tilting.

The interior of the bed and sides is lined with galvanized sheet steel to protect the wood from undue wear.

Here are the hopper cars in use.