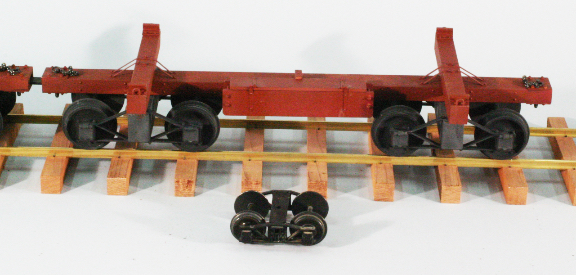

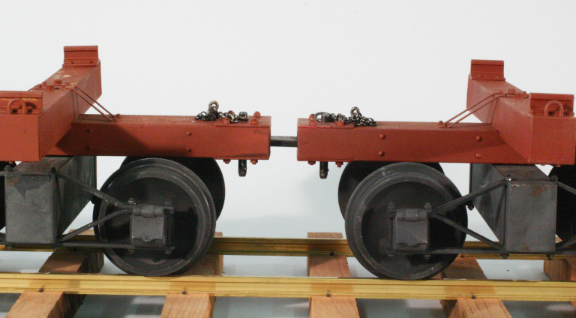

The "Making Trucks" page describes the process I use, which evolved over time, since I have now fabricated 15 pairs. The picture here is my very first effort, the beginning of the entire rairload.

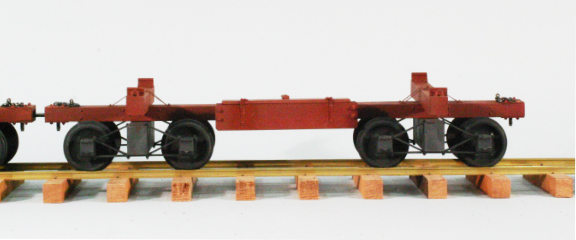

I want to haul actual firewood, which is about 16" long, and set the basic car length at 20". After a little research on the web and in my library, I designed a simple skeleton log car, and set out to build a set of three. I am a woodworker, so my shop made this kind of fabrication easy.

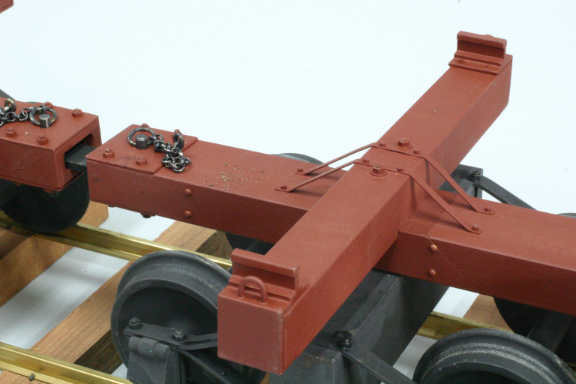

To secure real logs, I needed to make the hook assembly at the end of each log bunk robust and well anchored. Looking at pictures of skeleton cars showed a variety of ways the log bunks were attached to the spine. Throughout the construction, I used nails or bolts to connect parts, which makes the model more of a miniature of the actual log car, and insure long lasting operation. The log bunk ends are brass channel, nailed to the arm, with a chain anchor loop soldered to the inside of the channel. The piece of rail soldered to the channel, protects the anchor loop for log damage.

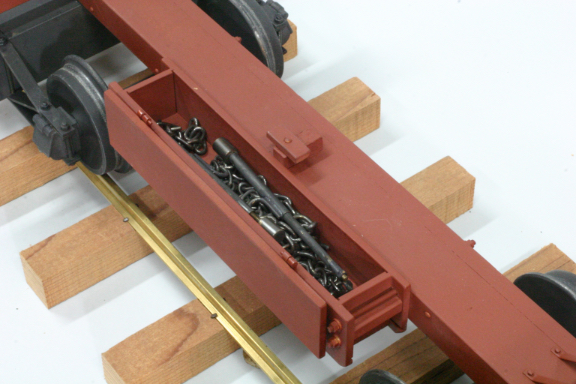

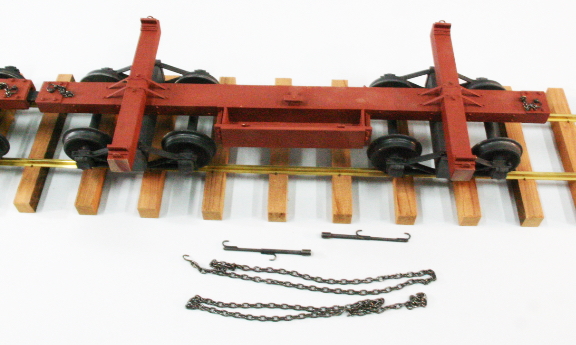

I also needed strong scale chain for the task and a way to tighten the chains onto the logs. I bought brass, hard soldered, chain from an English model boat supplier, and fabricated chain binders from brass tube and 2-56 threaded rod. I added a box to each car, which holds the chains and binders. It is very easy to place a log on the car, and then chain it down securely.

I made the coupler pocket generous enough that these cars can easily traverse a 5' radius curve. At first, the link was a piece of 1/8" x 1/2" brass bar stock. I found I needed more curve clearance, and have now changed the center of the links to a rod. For pins I use commercial pull pins, secured to the cars by short pieces of chain. Metal plates above and below the wooden pocket are secured with 2-56 threaded rod and nuts to transfer the load from the pin to the spine of the car.

I am very pleased with how these cars turned out. Building something new always involves a lot of design decisions, which is slow at first. Now I have patterns for trucks and couplers, and a design philosophy of using mechanical fasteners wherever I can. Future rolling stock will build on these decisions. I have decided that in addition to the firewood industry, this railroad will haul water, dirt, rocks, and service the patio with food and beverages.

One last picture is a comparison between one of these new cars and a Bachmann "G" scale truck.